Introduction:

In the pharmaceutical sector, many production facilities face challenges associated with obsolete systems designed based on outdated requirements. The need for extraordinary maintenance interventions becomes essential to keep the plants efficient and compliant with production standards.

Current Situation:

The purified water system, consisting of a dual-stage osmosis and electrodeionization system, experienced frequent leaks from numerous clamp junctions during the winter season and an increase in the conductivity of produced water in the summer season.

In a reverse osmosis process, the temperature of the feedwater has significant effects. Specifically, with an increase in temperature, the concentration of salts in the permeate also increases at a constant production flow. This is partly due to the relaxation effect in the internal bonds of the membrane.

Temperature also affects the permeate flow; as it increases, a lower feed pressure is sufficient to produce a given quantity of permeate.

Conversely, with decreasing temperature, to ensure the same quantity of permeate, it is necessary to increase the feed pressure, resulting in increased stress on the membranes and the entire system.

Solution:

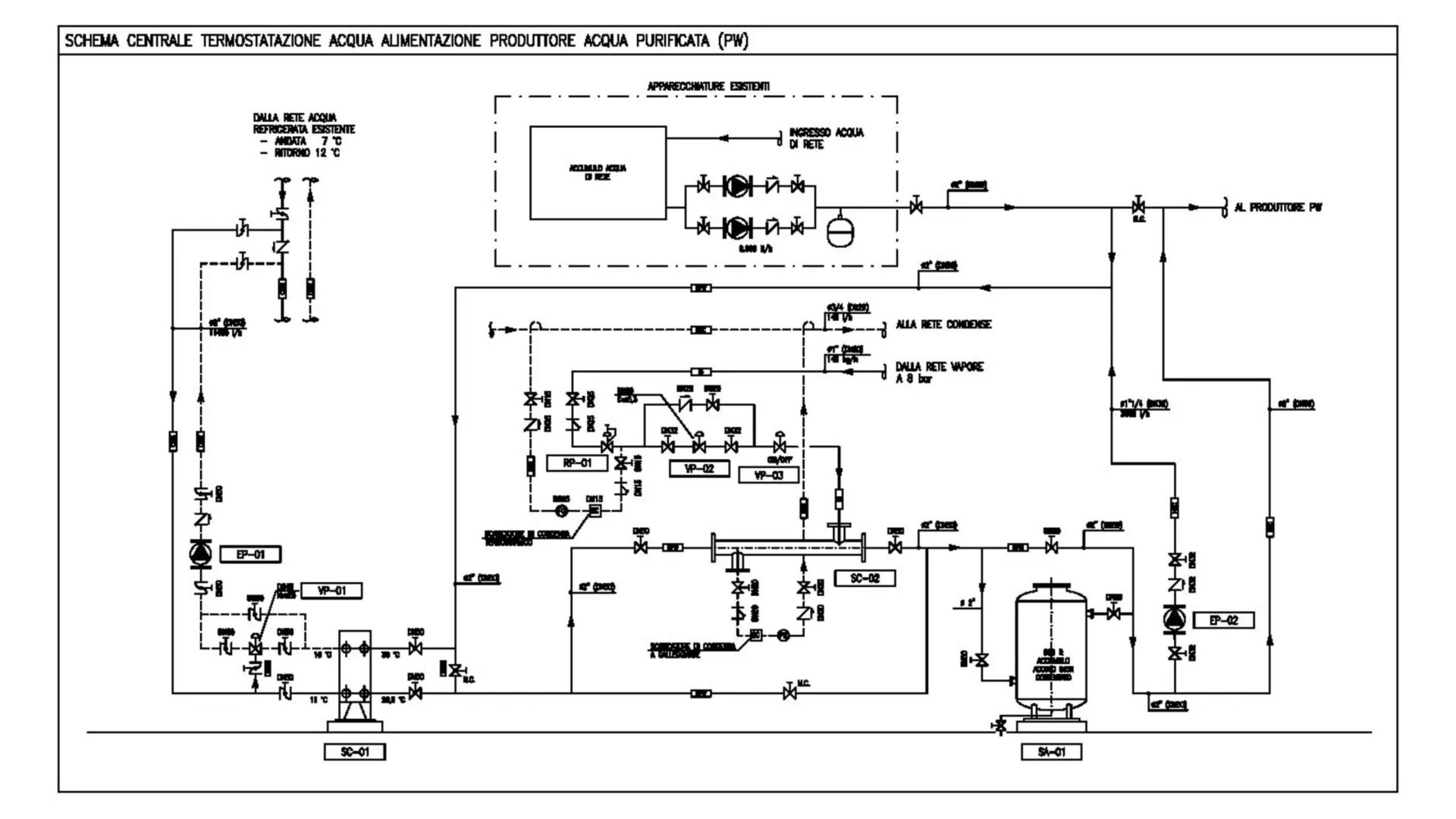

TECMA has implemented a thermostatic control system at the inlet of the reverse osmosis process to ensure a constant temperature throughout the year.

The system consists of two heat exchangers in series, one for cooling and one for heating, along with a recirculation system with a 500-liter inertial storage.

The control system ensures an outlet temperature between 15 and 20°C, ideal for the proper functioning of a reverse osmosis producer.

In conclusion:

The solution implemented by TECMA offers several advantages.

Firstly, it extends the average life of the membranes, contributing to the preservation of the entire plant.

Temperature regulation reduces stress on the electro-pumps and connections, limiting any plant shutdowns caused by breakages or leaks. Additionally, during the summer periods with particularly high-water temperatures, exceeding 25°C, the permeate conductivity remains unchanged, limiting the passage of salts through the membranes.

This solution not only enhances the operational efficiency of the plant but also contributes to the long-term sustainability and stability of the purified water production process.

Articoli correlati

June 7, 2024

Circular Strategies in the Life Science Industry

Circularity and life cycle assessment are foundational pillars of…

May 21, 2024

Sustainability in the Pharmaceutical Industry: Conservation of Resources

Discover the innovative solutions we are implementing in the pharmaceutical…