The original language release (Italian) is the official and authorized version of the release. This translation is only a means of assistance and should be compared with the original language text, which is the only version of the text that will be legally valid.

It’s not an extra cost. It’s an added guarantee.

In the pharmaceutical sector, plant design is a highly complex challenge. Even a minor design error can lead to major consequences: project delays, regulatory non-compliance, additional costs, or—at worst—safety risks for personnel.

Designing facilities in compliance with GMP (Good Manufacturing Practices) requires absolute precision, coordination among multiple stakeholders, and a level of foresight that goes beyond traditional 2D drawings.

In this context, tools like Building Information Modeling (BIM), Virtual Reality (VR), and Augmented Reality (AR) now offer concrete solutions to these demands. These are not “tech accessories,” but operational tools already integrated into established workflows, delivering tangible benefits from the earliest stages of the project.

BIM: The solid foundation for everything

The first point to clarify is that without a well-structured BIM model, VR and AR cannot exist. BIM is not a software, but a methodology—a design approach that enables the creation of a 3D digital and data-rich model of the facility, where each element contains technical data, spatial relationships, and functional logic.

Thanks to BIM:

• All professionals involved (designers, engineers, clients, installers) work on a single, constantly updated model.

• Design issues can be anticipated early (clash detection, accessibility, ergonomics).

• The groundwork is laid for immersive technologies.

Virtual Reality for design review and training

Once the BIM model is created, it can be transformed into an immersive, navigable environment using Virtual Reality.

In pharmaceutical design, VR-based design reviews are especially effective for:

• Actively involving the client in the design process, even without technical expertise.

• Verifying operator workflows, access to utilities, and flow consistency (personnel/material).

• Gathering timely feedback before moving to the execution phase.

But VR goes further—it becomes a valuable tool for training personnel who will work in the production area: simulating complex operational procedures in a safe and realistic environment, optimizing timelines, demonstrating tasks during production downtime, and reducing the risk of errors once in the real environment.

Augmented Reality for construction and maintenance

At the same time, Augmented Reality finds direct application on-site and during quality control activities. By projecting the BIM model into the real environment via tablets or headsets, it’s possible to:

• Verify correct installation against the design.

• Compare real-time progress with the digital model.

• Support inspection and commissioning activities.

AR also proves useful post-construction, for maintenance or revamping operations. Technicians can access technical data simply by pointing their device at the relevant element—saving time searching for information and simplifying complex tasks, while reducing the risk of human error.

Not just for large companies: Accessible technology

One of the most common objections is that these technologies are reserved for large companies with big budgets. In reality, BIM-based design has been implemented in structured firms like ours for over 10 years, and is now fully integrated into our processes.

This means it doesn’t require additional effort or cost.

The initial investment quickly pays off through:

• Fewer design revisions.

• Reduced errors on-site.

• Optimized training and plant start-up.

A shift in mindset, not just technology

Adopting BIM, VR, and AR is not just about tools—it’s about a design culture. It means shifting focus from execution to foresight, from correction to anticipation, from “problem management” to “information management.”

In the pharmaceutical sector, where time is money and quality is a regulatory requirement, these tools are not optional—they’re a competitive advantage.

In collaboration with Giovanni Cuciniello, BIM Manager, and Andrea Daviddi, CDE Manager.

Articoli correlati

July 17, 2025

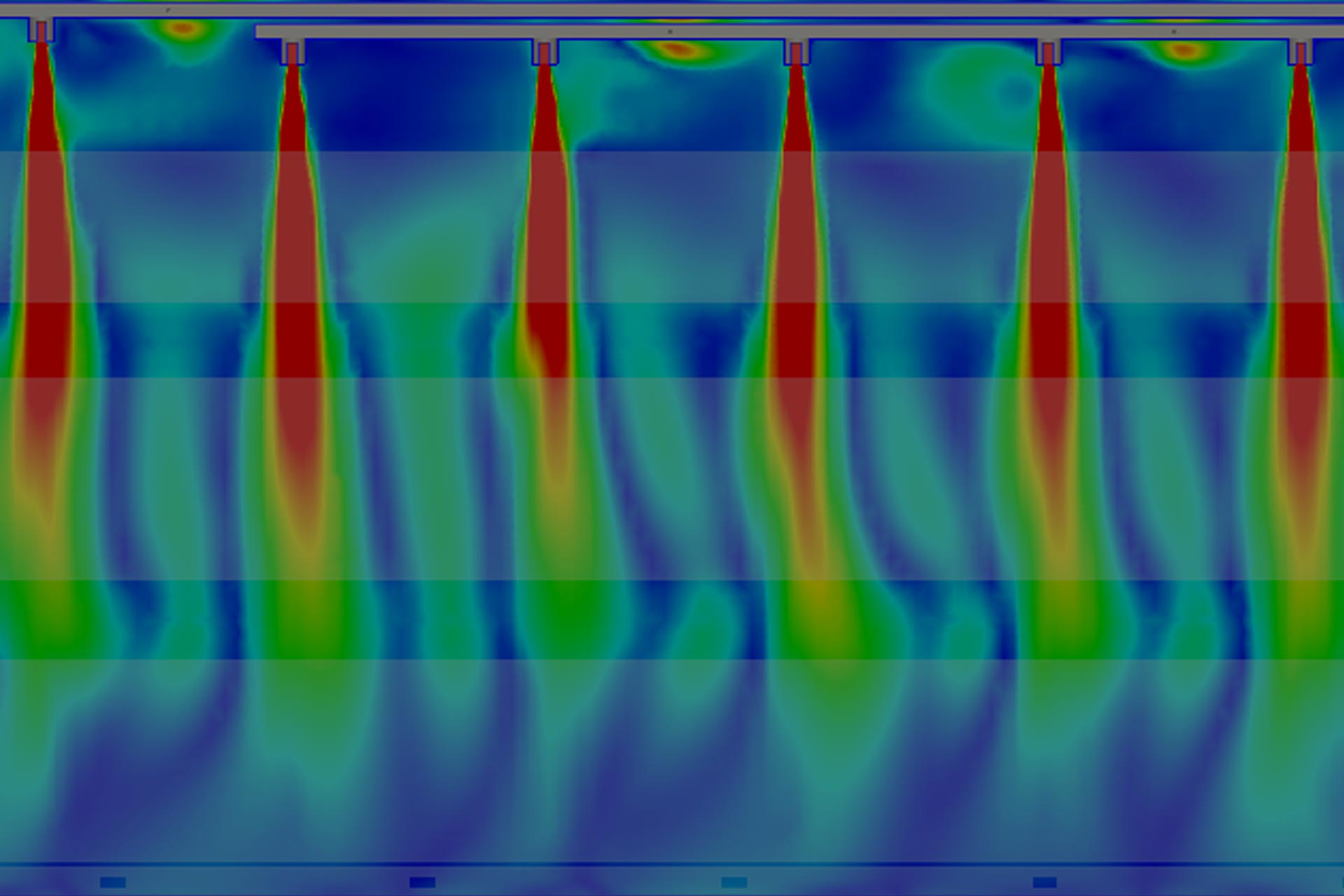

Designing with Computational Fluid Dynamics (CFD)

For over ten years, Techniconsult has been incorporating Computational Fluid…

February 13, 2025

AI and BIM design: a new era for architecture and engineering

One of the most promising innovations is the integration of Artificial…

February 28, 2024

Advantages of computational fluid dynamics (CFD)

Nowadays, issues related to the study of fluid dynamics are becoming…