The original language release (Italian) is the official and authorized version of the release. This translation is only a means of assistance and should be compared with the original language text, which is the only version of the text that will be legally valid.

Designing Pharmaceutical Warehouses with CFD

For over a decade, Techniconsult has been integrating Computational Fluid Dynamics (CFD) simulation into its engineering activities serving the Life Science sector. Thanks to advanced software tools, CFD makes it possible to simulate the thermo-fluid dynamic behavior of any type of ventilated system. This enables the design process to be guided and its outcomes anticipated, drastically reducing the risk of errors. In fact, this capability is becoming increasingly important, as the growing complexity of projects demands a combination of high-quality standards with the increasingly relevant issues of energy saving. It’s no coincidence that pharmaceutical warehouses—dedicated to the storage and distribution of drugs and related products—are fully part of this context.

For this reason, Techniconsult uses CFD simulation in the design, review, and optimization of various types of warehouses.

Given that this type of environment must ensure a significant internal volume and, generally, the vertical development that characterizes most of them, the most challenging issue to solve—whether in the design of a new building or in corrective interventions on an existing one—is to ensure adequate distribution of airflow and, therefore, good temperature uniformity within the space.

Designing New Buildings

CFD simulation can accurately anticipate thermal mapping and, consequently, the results of the Performance Qualification of a new warehouse already during the design phase.

In fact, it is possible to simulate the performance of the HVAC system under various external environmental conditions, evaluating different distribution layouts, airflow rates, and the thermo-hygrometric characteristics of the air, all based on the Client’s final objective.

For example, we can monitor the maintenance of a specific average temperature inside the building; the reduction of energy consumption by avoiding unnecessary oversizing; compliance with specific thermo-hygrometric conditions required to prevent product degradation; or adherence to specific requirements established by GMP regulations.

Finally, CFD software provides numerous tools for result analysis and various visualization modes, which are useful depending on the type of parameter—global or local—that is of greatest interest.

Iterative and Interactive Analysis of the HVAC System During the Design Phase.

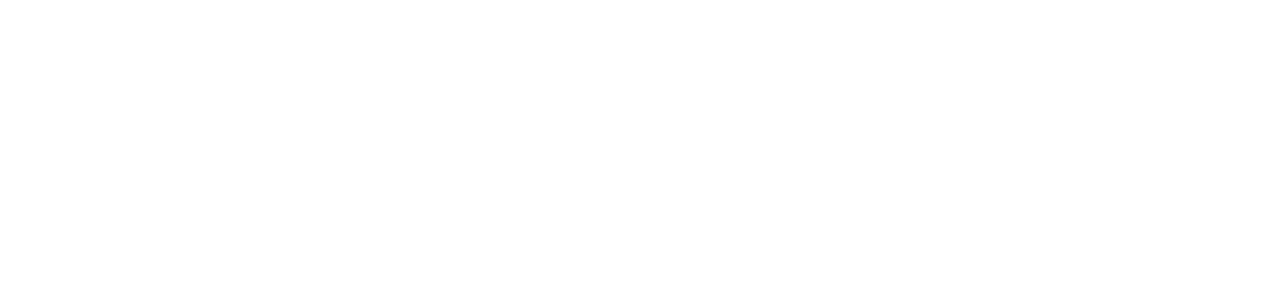

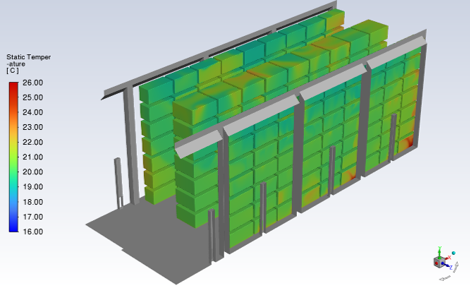

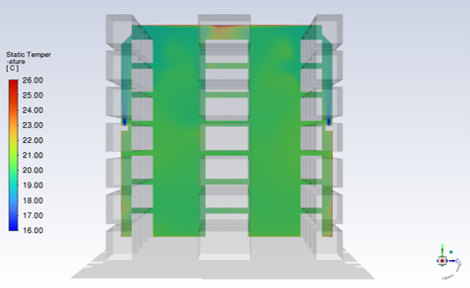

CFD Simulations Performed Under Summer and Winter Design Conditions: Temperature Maps.

Layout 1 – Winter

Layout 2 – Winter

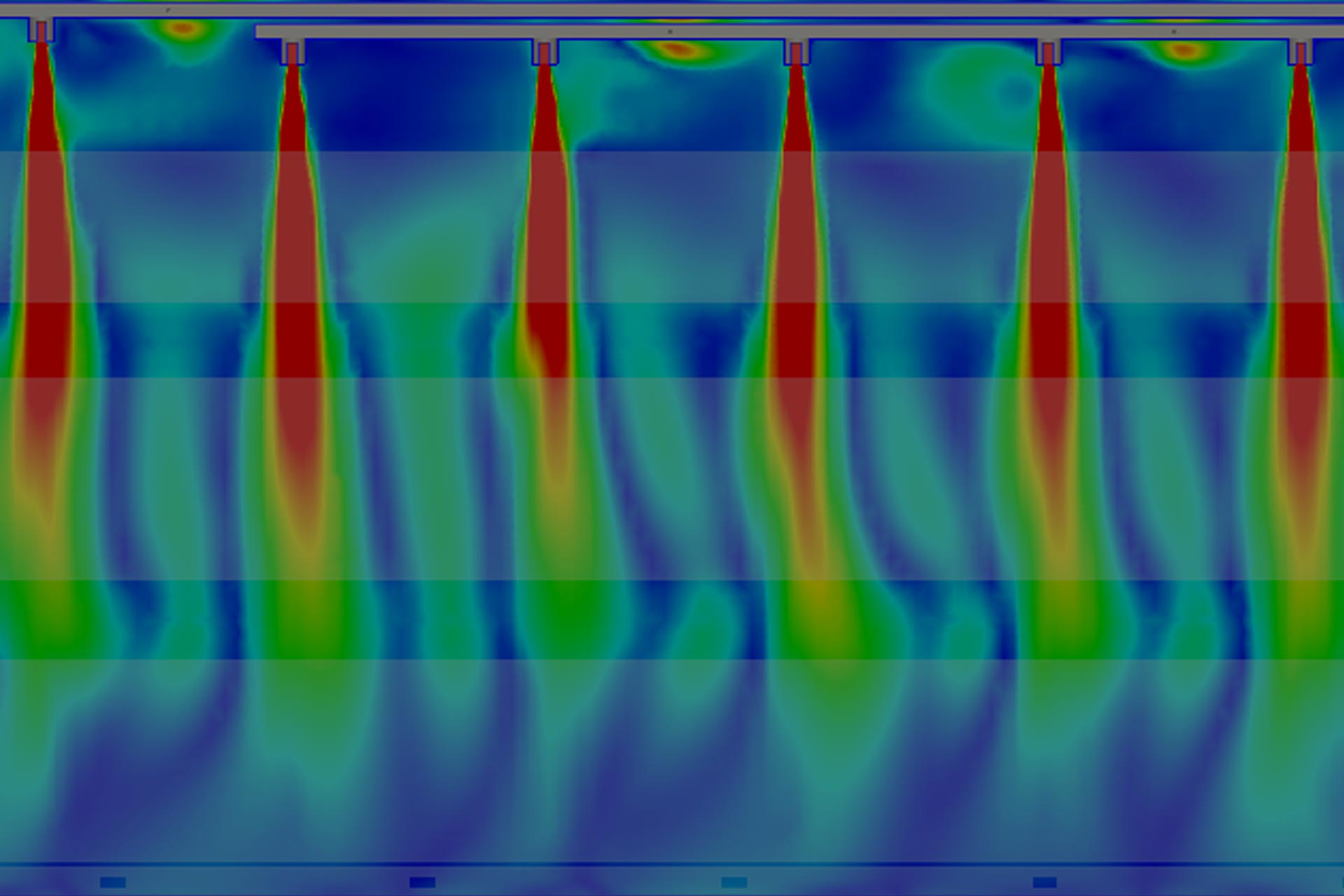

Evaluation of Thermo-Fluid Dynamic Performance Integrated into the Design Process, Aimed at Layout Optimization and Airflow Rate Definition.

Layout 1 – Summer

Layout 2 – Summer

Corrective Actions or Revamping of an Existing Building

In the case of corrective actions or revamping of an existing building, the main advantages of CFD—beyond those already mentioned for the design phase—include the ability to simulate and therefore closely study the current functioning of the building in all internal load configurations and under all operating modes of the dedicated HVAC system.

This makes it possible to thoroughly investigate the critical issues for which the Client is requesting a corrective intervention (which may be related to the system or the building structure) and to propose targeted solutions aimed at eliminating or reducing these issues.

Subsequently, CFD simulation allows for the proposed solutions to be validated in advance and, if required by the building-system configuration (or even by the Client), enables the division of the solutions by intervention area and the planning of their implementation in successive phases.

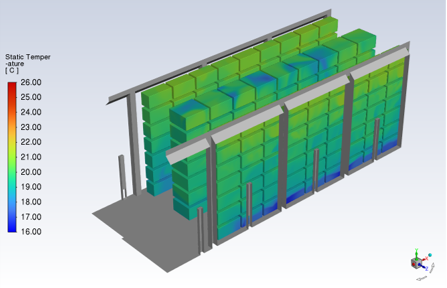

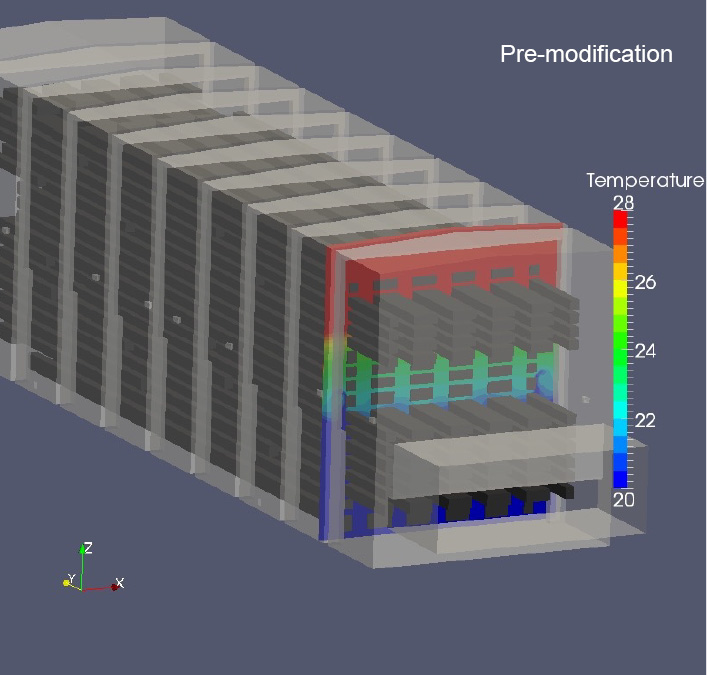

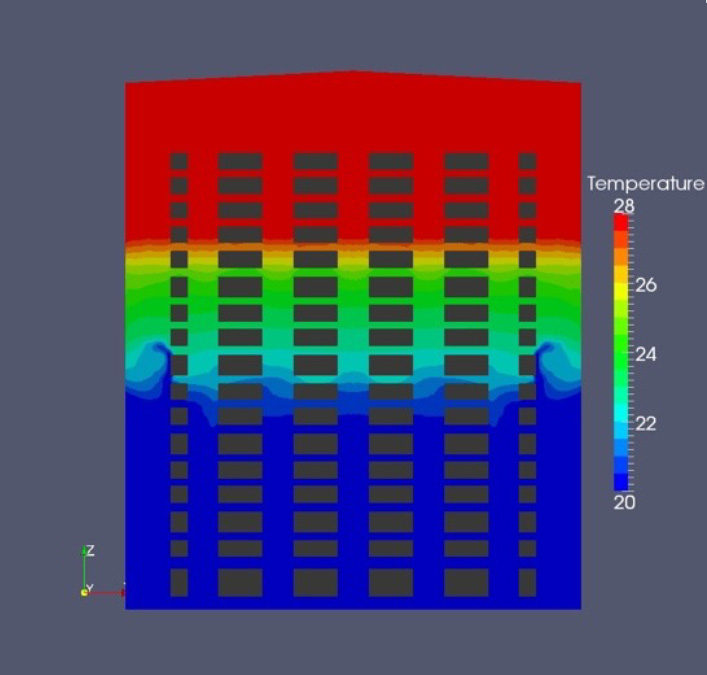

Request for HVAC Revamping Following the Detection of Frequent Temperature Sensor Out-of-Range Events.

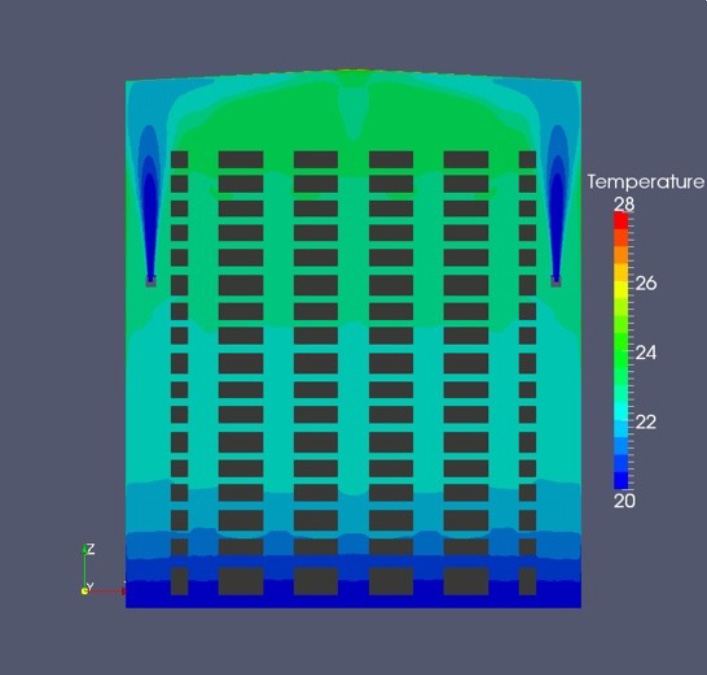

CFD simulation highlighted a serious problem of thermal stratification in the vertical development of the warehouse.

Layout 1 – Before the modification

Layout 2 – Before the modification

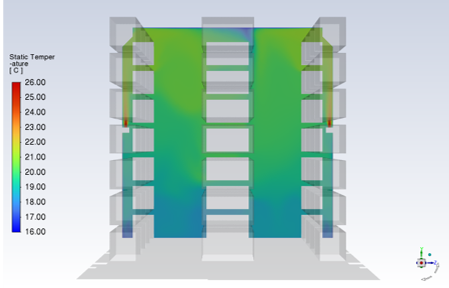

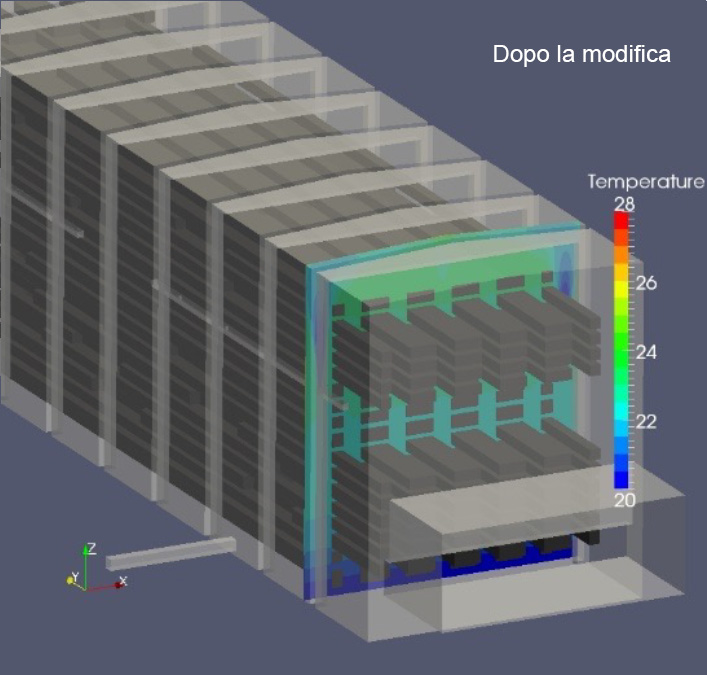

The design solution adopted led to a significant reduction of the temperature gradient and an improvement in the uniformity of air distribution.

Layout 1 – After the modification

Layout 2 – After the modification

Articoli correlati

July 29, 2025

BIM, VR and AR in Pharmaceutical Design: Efficiency, Control and Integrated Quality

In the pharmaceutical sector, plant design is a highly complex challenge. Even…

February 13, 2025

AI and BIM design: a new era for architecture and engineering

One of the most promising innovations is the integration of Artificial…

February 28, 2024

Advantages of computational fluid dynamics (CFD)

Nowadays, issues related to the study of fluid dynamics are becoming…